Realising we were in need of a CNC machine for foam cutting, we checked out rcKeith open source hot wire plans and built our own for the Project Air workshop. Here’s how.

First, check out this second channel vid on the build (and subscribe).

This project started with a dig through all the resources available on rcKeith.co.uk as well as the many videos and updates he's added to his channel.

The build process consisted of two different parts, the electronics and the mechanical build.

For the electronics, I installed custom firmware provided by Keith onto an Arduino Mega 2560. This would be the base of our electronics system.

On top of this board, I installed a RAMPS 1.4 shield to control the four motors needed to operate the machine. This ramps board also housed the drivers required for our Nema 17 motors.

I installed the GRBL hot wire software and made sure it could link with my Arduino as well as accurately control the motors.

With this complete, we could move onto the mechanical section of the build and cut out all the MDF pieces needed.

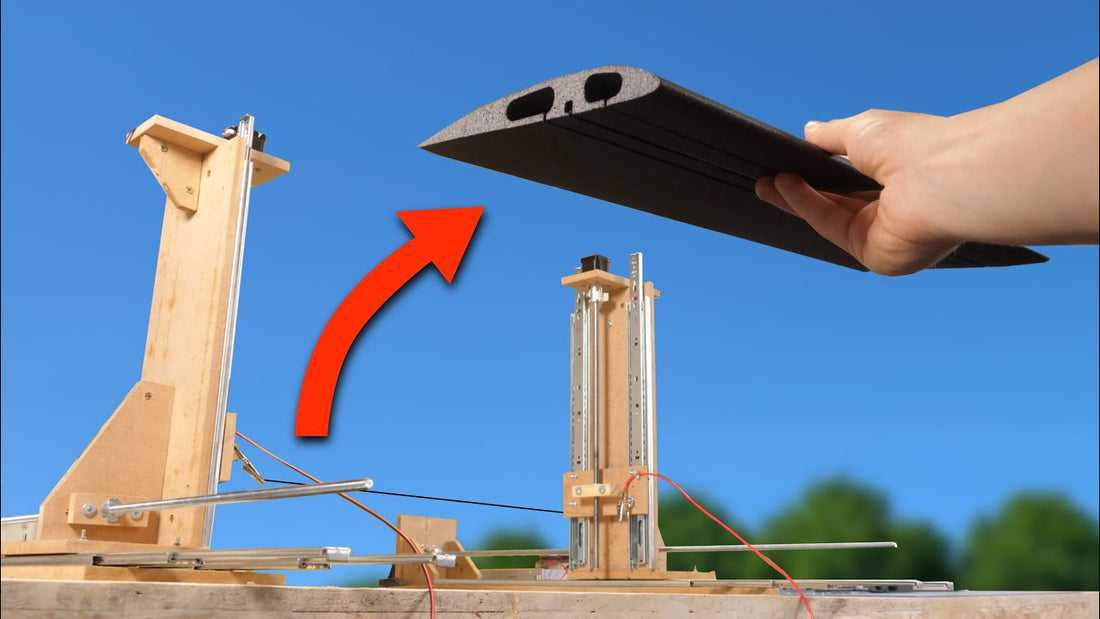

Draw slides, threaded rods, couplers, motors and other fixings were all installed onto the MDF as it was assembled into the two mirrored towers.

I ran 0.4mm nichrome wire between the two towers with a spring on one side to compensate for the change in tension as the wire expands with the heat.

The wire was powered by its own benchtop power supply unit, separate from the PSU used for the Arduino assembly.

After some calibration and adjustment, the machine was complete and could successfully run g-code through the GRBL software to cut our very own foam wings.

Big thank you to Keith for creating these amazing plans and putting them up as open source!

If you enjoyed these behind the scenes extras check out more on the Project Air second channel, Project Air 2!

Or, if you want to read some more articles on our projects we have plenty more over here.